Wheatstone came home with three

Best of Show awards

- Radio World Best of Show 2024 for our Layers virutalization with MPX over IP transporter to create the infinite studio capable of sharing media, workflows and resources across distances.

- Radio World Best of Show 2024 for our sleek new DML digital console line made for Audioarts budgets but built to top-line Wheatstone standards.

- TV Technology Best of Show 2024 for our Strata Virtual Mixer for mixing anywhere, for any purpose.

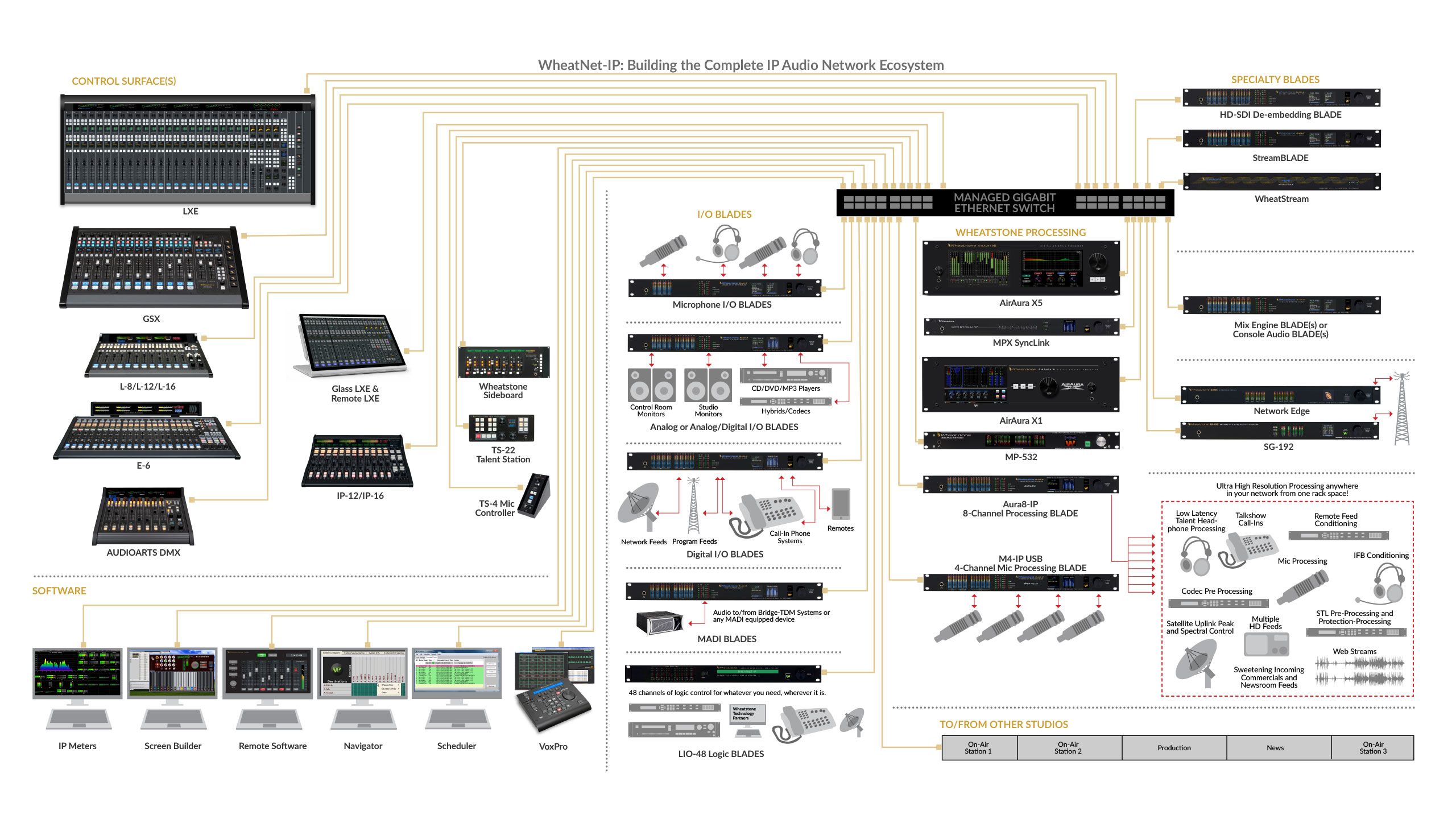

Complete AoIP Broadcast Ecosystems

Audio mixing consoles/surfaces. IP routing and control. Audio processors. Digital editing tools.

Wheatstone's products and studio systems are designed and built specifically for the demands of broadcasting. They cover a range from smaller single-station studios to large multi-studio, multi-station complexes with a million cross-points and dozens of mixers, talent stations, and elements connected across a region. Broadcast grade AoIP software, devices, consoles, talent stations, and appliances, all engineered, manufactured and supported by your number one industry partner.

Wheat:News

HIGHLIGHTS

By Dan McQuillin, Broadcast Bionics

If you’ve been holding off moving to a SIP phone system because of the complexity, here’s one simple solution that fits easily into your WheatNet IP facility. Broadcast Bionics’ Dan McQuillin explains. You can check out Caller One with our LXE console surface at BGS booth C2808 during the NAB show.

You might have already seen this photo of Leighton’s studio with the spectacular strip of blue lighting along the edge of the furniture. What you can’t see here is the coffee pot that DOE Tony Abfalter “WheatNet-IP’d” to a studio console. He’s done the same with door locks and security systems and, yes, this string of LED lighting, which changes from blue to red to bright orange depending on studio status. After all, this is the DOE who WheatNet IP’d everything and anything possible in all seven Leighton markets before heading to Antarctica for the National Science Foundation on temporary hiatus.

By Dominic Giambo, Manager of Technology

This upcoming NAB show, you’ll hear us talk about Reliable Internet Stream Transport (RIST) as it relates to cloud and moving media across the public internet. Here, Dominic Giambo, Wheatstone’s Manager of Technology, explains what RIST is and why it’s important in his technical paper published in the December 2023 issue of Radio World Engineering Extra.

JOIN THE CLUB

We hope you'll come along with us at Club Wheat by clicking on the SUBSCRIBE button below to begin receiving Wheat News in your email inbox every month.

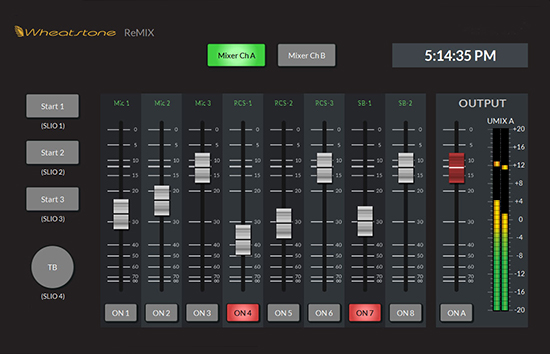

Mix, route and trigger elements, functions or events anywhere on any device.

Home or studio. Phone or console surface. Single location or multiple locations. WheatNet-IP touches everything.

Simplify your operation.

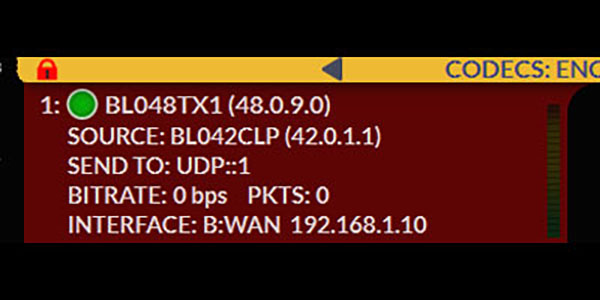

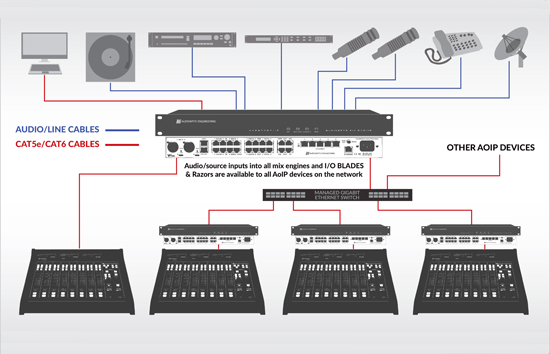

WheatNet-IP is the only AoIP combining logic control with routable audio tools such as utility mixers, audio processing, streaming encoders and embedded CPU as part of the AoIP native environment.

Eliminate racks and rooms of hardware.

Everything from mic processing to streaming appliances and automation integration is in one native AoIP environment.

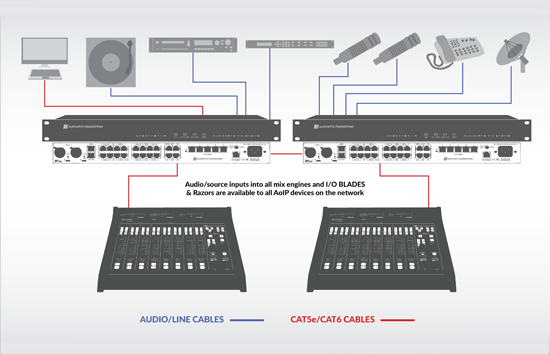

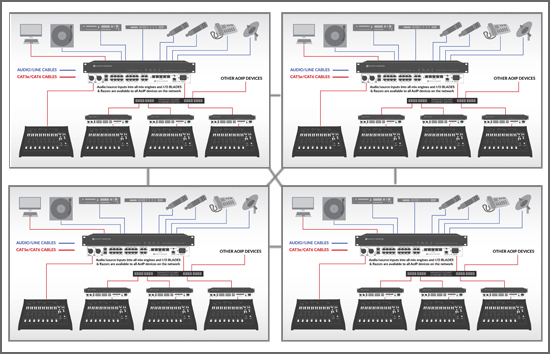

Combine regional studios in one AoIP environment.

Opus and AAC codecs as part of the AoIP let you share studio resources and talent across a WAN. AES67 compliance and NMOS support give you access outside the network.

Easy setup.

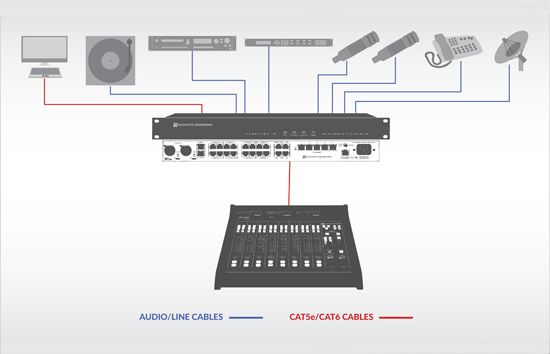

Unbox and let WheatNet-IP Blades do the rest. Each Blade is self-aware and self-configuring. No IP addressing required. Save your engineering resources for more important tasks.

Your Studio. Your Way.

Console surfaces, talent stations and unlimited virtual interfaces to choose from. Customize your AoIP system for your studios now, and add on appliances, elements, and virtualization later.

No Studio Too Small. No Studio Too Big.

Go from analog to AoIP in a snap. IP audio networking and mixing console in one, Ethernet switch included. Just add CAT6 cable (actually, we include that too...)

What Can Wheatstone Do For You?

Total Remote Access

Wheatstone has software and hardware solutions that allow you remote access and control over everything and everyone in your system from anywhere.

Virtual Tools

WheatNet-IP offers a full set of virtual control, processing, and communication tools with which you can tailor your workflow.

Engineering Services

When planning your studio, your Wheatstone Sales Engineer can help you plot it all out to the smallest detail.

Build Your System

While we source parts from around the world, everything we make is built in our US factory in the town where we live, and parts for almost everything we’ve ever built are readily available.

Join the Wheatstone Network

Manufacturing, engineering and end-to-end studio support backed by the industry's leading AoIP supplier in the broadcast industry with thousands of studios in operation around the globe.

Did we mention Emmy-award-winning? In 2020, Wheatstone won an Emmy for “development of synchronized multichannel uncompressed audio transport over IP networks" which led to the implementation of the AES67 standard.

Contact us at [email protected]

READ WHEATSTONE'S PRIVACY POLICY | ACCESSIBILITY | TERMS OF USE